What is Nano Bacterial Cellulose?

Fermentation-derived nanocellulose (bacterial cellulose) is a polysaccharide biomaterial composed of glucose monomers linked by β-1,4-glycosidic bonds, essentially a polymer of glucose. Its unique structure and excellent physicochemical properties provide broad application potential across numerous fields.

Chemical Nature and Structural Characteristics

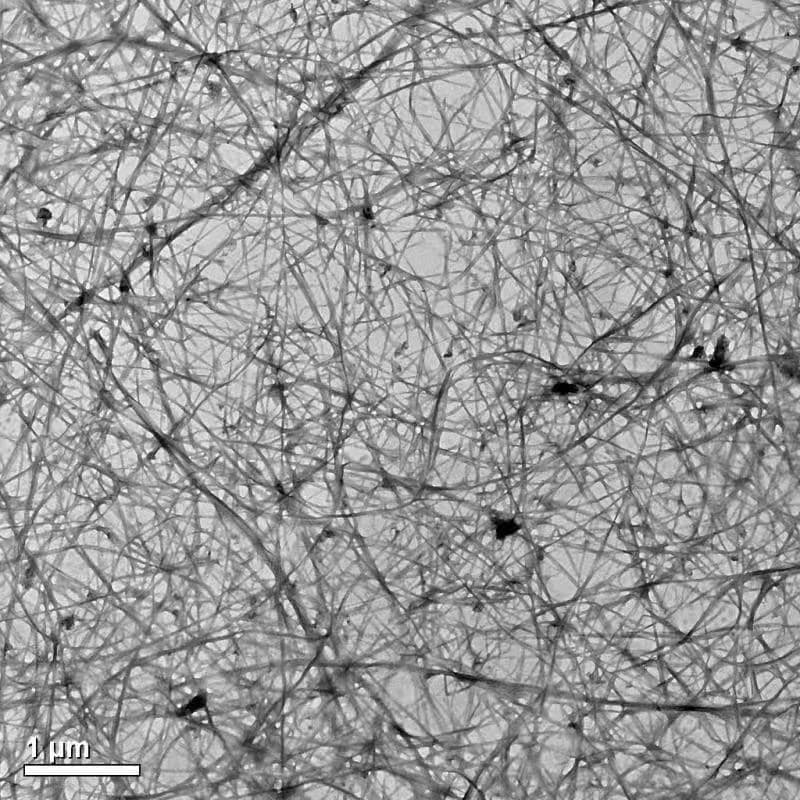

Chemical compositionNano bacterial cellulose is a linear polymer formed by glucose monomers linked through β-1,4-glycosidic bonds. Its fiber diameter ranges from 20 to 40 nm, with lengths reaching the micron scale, resulting in an ultrafine fibrous network.

BiosynthesisUsing biotechnological fermentation processes and sugars (such as glucose) as raw materials, it utilizes cellular metabolism to convert sugars into polysaccharide cellulose.

INCI NameIn the cosmetic ingredient directory, the INCI name for fermentation-derived cellulose is CELLULOSE, with an EINECS number of 232-674-9.

Structural Characteristics

Three-Dimensional (3D) Network StructureIn liquids, bacterial cellulose can form a stable three-dimensional network structure, which enables it to deliver active ingredients efficiently and provides excellent emulsification, thickening, and suspension properties.

Ultra-high Specific Surface Area and Aspect RatioDue to its ultrafine fiber diameter and high aspect ratio, bacterial cellulose possesses an extremely large specific surface area, enabling efficient adsorption and loading of active ingredients.

High Purity, High Crystallinity, High Degree of PolymerizationBacterial cellulose has a high purity, free of impurities such as lignin and hemicellulose. It also has a high crystallinity and degree of polymerization, making it suitable for demanding fields such as medicine.

High Water-Holding CapacityThis material can absorb and retain a large amount of water, providing excellent water-holding performance, making it suitable for moisturizing products.

High Young’s ModulusIt has excellent mechanical strength and a high elastic modulus, which can enhance the mechanical properties of the material.

Property 1: Strong Water Retention Capacity (Water Retention Values, WRV)

The bacterial cellulose of NatFibra™ exhibits excellent water-holding performance due to its polyhydroxy structure from glucose monomers.

1. Nanoscale Fiber StructureNatFibra™ has a fiber diameter of only 20–40 nm, forming an ultrafine fibrous network. This nanoscale structure creates a huge specific surface area, allowing it to adsorb and retain a large amount of water molecules.

2. Three-Dimensional (3D) Network StructureThis structure not only allows water adsorption, but also prevents water evaporation or loss.

3. High Water Retention Value (WRV)NatFibra™ exhibits significantly superior water retention capabilities compared to conventional cellulose materials, with the ability to absorb and retain water several dozen to even a hundred times its own weight.

The advantage of water retention capability

Long-lasting moisturizationIn cosmetics, NatFibra™ can provide long-lasting moisturization for the skin, making it particularly suitable for use in products such as masks, serums, and moisturizers.

Softness and comfortThe high water retention capacity keeps the material soft and moist, making it suitable for applications requiring high comfort, such as medical dressings and wound care.

Feature 2: Uniform dispersion without altering the liquid viscosity, serving as a green suspension stabilizer.

The fibrils of NatFibra™, due to their unique "nanoscale" three-dimensional (3D) network structure, enable uniform distribution and stable suspension of active ingredients without significantly increasing the viscosity of the liquid.

1,Key Features

Forms an invisible and insoluble three-dimensional network structure.The nanofibrils of NatFibra™ form a stable three-dimensional network structure in water, which is invisible and insoluble within the system. This structure can effectively entrap fine particles of active ingredients.

Enhances the suspension capacity without increasing the perceived viscosity.Unlike traditional thickeners, NatFibra™ provides excellent suspension performance without significantly increasing the liquid’s viscosity, thereby maintaining a light and pleasant formulation texture.

Suitable for formulations with broad rheological profiles.Whether in low-viscosity or high-viscosity systems, NatFibra™ can effectively perform and is suitable for formulations with various rheological profiles.

Excellent stability across temperature, pH, and salinity.NatFibra™ remains stable across a wide range of temperatures, pH levels, and salinity conditions, making it suitable for use in various complex environments.

2. Working Principle

Nanoscale fiber networkThe fiber diameter of NatFibra™ is only 20–40 nm, forming an ultrafine three-dimensional network structure that effectively traps fine particles of active ingredients in the liquid system, preventing them from settling.

Suspension stabilityThe active ingredients are uniformly dispersed and fixed within the three-dimensional network, thereby achieving long-term stable suspension.

Viscosity controlSince the 3D fiber network of NatFibra™ is a physical mesh, it does not significantly increase the viscosity of the liquid, preserving the original texture of the formulation.

Feature 3: Efficient delivery of active ingredients to the skin’s surface.

The fibrils of NatFibra™ not only stabilize the suspension of active ingredients, but also, thanks to their unique three-dimensional (3D) network structure, efficiently deliver these active ingredients to the skin’s surface.

1,Working Principle

Three-Dimensional (3D) Network StructureThe fibrils of NatFibra™ form a stable three-dimensional network structure with nanoscale diameters in water, capable of carrying and locking active ingredients. Similar to the way plants use vascular bundles to transport nutrients, the fiber network of NatFibra™ continuously delivers active ingredients to the targeted area.

Microcirculatory deliveryThe active ingredients are gradually released and penetrate the skin’s surface through the three-dimensional network of NatFibra™ in a microcirculatory manner. This delivery method prevents the rapid loss of active ingredients, ensuring their long-lasting and sustained activity.

Efficient penetrationThe nanoscale fiber structure can closely interact with the skin’s surface, promoting the penetration and absorption of active ingredients.

2. Key Features

Sustained releaseThe active ingredients are uniformly dispersed within the three-dimensional network, enabling slow and sustained release, which prolongs their activity.

Efficient deliveryThrough a microcirculatory mechanism, NatFibra™ can efficiently deliver active ingredients to the skin’s surface, enhancing absorption efficiency.

Enhanced efficacyThe stability and permeability of the active ingredients are enhanced, allowing them to exert their efficacy more effectively.

Gentle and safeNatFibra™ itself possesses high biocompatibility, making it suitable for use on sensitive skin.

The high-efficiency delivery capability of NatFibra™ grants it significant application value in the cosmetics and pharmaceutical fields, as it can substantially enhance the delivery efficiency and absorption of active ingredients, providing consumers with a better experience and improved efficacy.

Feature 4: Pickering Emulsion

Thanks to its ultrahigh aspect ratio (diameter of 20–40 nm and length in the micron range), the fibrils of NatFibra™ exhibit excellent performance in Pickering emulsion systems.

1,Basic Principle of Pickering Emulsion:Pickering emulsions are emulsions stabilized by solid particles rather than traditional surfactants. The solid particles adsorb at the oil-water interface, forming a physical barrier that prevents droplet coalescence, thereby stabilizing the emulsion.

2. Advantages of NatFibra™ in Pickering Emulsions

Ultra-high aspect ratioThe fiber diameter of NatFibra™ is only 20–40 nm, with lengths reaching the micron scale. This ultra-high aspect ratio allows it to efficiently adsorb at the oil-water interface, forming a stable physical barrier.

Excellent emulsifying performanceNatFibra™纤维丝能够在油水界面形成致密的三维网络结构,有效防止液滴聚并,提升乳液的稳定性。

Good flowabilityPickering emulsions constructed with ester components exhibit excellent flowability, making them suitable for applications such as sprays.

Green and environmentally friendlyNatFibra™ is produced through biotechnological fermentation and is naturally biodegradable, aligning with the principles of green chemistry.

Feature 5: Skin Repair, Safe and Green

Thanks to its high purity, excellent biocompatibility, and multifunctionality, the cellulose in NatFibra™ demonstrates tremendous potential in skin repair and medical applications. Here is a detailed explanation of its uses in skin repair and medical fields:

1,Core Advantages

High purityNatFibra™ is free from impurities such as hemicellulose and lignin, making it a highly pure biomaterial suitable for use in medical and skin repair applications.

Excellent biocompatibilityNatFibra™ exhibits excellent compatibility with human tissues, does not cause immune rejection or allergic reactions, and is suitable for long-term use.

MultifunctionalityIt can be used alone or in combination with biopolymers, nanoparticles, and other materials to form multifunctional composites.

2. Applications in Skin Repair

Treatment of burns, wounds, and ulcersNatFibra™ can provide a moist environment for the wound, promoting cell growth and wound healing. Its three-dimensional network structure can retain moisture, prevent wound drying, and allow oxygen exchange, thereby accelerating the repair process.

Accelerates the epithelialization processNatFibra™ membranes promote the migration and proliferation of epithelial cells, accelerating the epithelialization process of the wound. Its dense structure can also effectively block bacteria and prevent infection.

Regulates cell adhesionNatFibra™ biocomposites can regulate cell adhesion behavior, providing an important feature for tissue engineering scaffolds and implants. This property has significant application value in regenerative medicine.

3. Other Applications in the Medical Field

Development of diagnostic sensorsThe ultrathin membranes of NatFibra™ have the ability to immobilize antigens, making them suitable for the development of diagnostic sensors. Their high specific surface area and biocompatibility make them ideal materials for biosensors.

Drug delivery vehicleThe three-dimensional network structure of NatFibra™ can carry active pharmaceutical ingredients, enabling sustained release and targeted delivery of the drugs.

Tissue engineeringAs a scaffold material, NatFibra™ can support cell growth and tissue regeneration, making it suitable for the repair of tissues such as cartilage and skin.